Möglichkeiten des 3D Drucks nach Branchen

Möglichkeiten des 3D Drucks nach Branchen

Besonders häufig kommt der 3D Druck in den folgenden Branchen zum Einsatz:

Automobilbranche

Medizintechnik

Maschinenbau

Motorsport

Luft und Raumfahrt

Konstruktionsbüro

Architekten & Messebau

Elektronik & Elektronische Geräte

Büromöbel

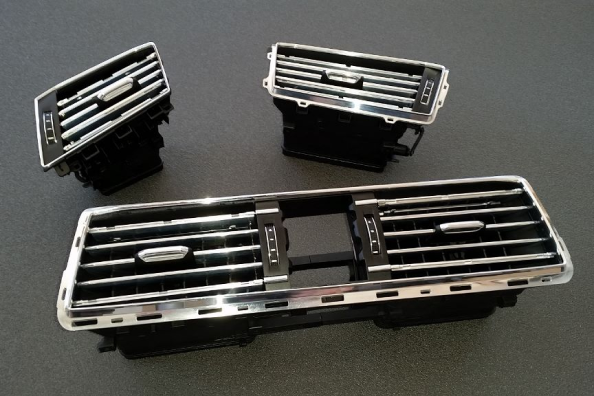

Die Automobilbranche

In der Automobilbranche herrscht seit je her ein großer Druck. Da ist einerseits der Preisdruck, der von allen Seiten ausgeübt wird. Doch man versucht die Konkurrenz nicht nur über den besseren Preis zu schlagen. Auch in Sachen Innovation geht es in der Automobilindustrie stets um höher, schneller und weiter.

Durch die Nutzung des Rapid Prototyping haben Automobilbauer die Möglichkeit, in der Forschung und Entwicklung sehr viel schneller zu arbeiten. Prototypen und Kleinteile verschiedenster Art können so schnell und besonders effektiv gedruckt werden. Neben einer schnelleren Produktion von testfähigen Prototypen bietet das 3D Druck Verfahren auch die Möglichkeit, störungsoptimierte Abgaskanäle zu fertigen.

Dabei entstehen Produkte, die den Brandschutzbestimmungen gemäß UL94-V0 entsprechen. Temperaturen bis 300 Grad Celsius können hier problemlos ausgehalten werden und auch die Beständigkeit in Bezug auf Chemikalien wie Kraftstoffe, Wasserstoff, Motorenöl und Ähnliches ist gegeben.

Seit über 25 Jahren sind wir ein zuverlässiger Zulieferer für die großen Automobilhersteller in Deutschland und ganz Europa und natürlich auch für deren Zulieferfirmen. Dank der jahrelangen Erfahrung in dieser Branche können wir auch Ihnen helfen, die Vorteile des 3D Drucks in Ihrem Unternehmen zu nutzen. So können wir Ihnen beispielsweise Normteile wie Gewindebuchsen oder Lager fertig umgossen oder umspritzt liefern. Selbst komplette Baugruppen können in einem Zug gedruckt und dann geliefert werden. So sparen Sie Zeit für eine ganze Reihe von Montageschritten.

- Interieur + Exterieur

- REACH/RoHS Konform

- Materialeigenschaften von PA6.6 ; PP, PE, ABS, TPE etc.

- Brandschutz gemäß UL94-V0

- Hochtemperaturbeständig bis über 300°C

- Beständigkeit gegen Chemikalien wie Kraftstoff, Motoröl, Wasserstoff, etc.

- Endlackiert

- Normteile wie Gewindebuchsen oder Lager direkt umgossen/umspritzt

- Jede Größe herstellbar

- Komplette Baugruppen vormontiert geliefert

Geeignete Technologie: Vakuumguss, MJF, SLS

Medizintechnik

Auch in der Medizintechnik war der 3D Druck von Anfang an recht beliebt. Wobei es anfangs tatsächlich eher noch schöne Träume waren. Eines Tages Prothesen drucken zu können, die individuell an die Bedürfnisse der Person, die diese tragen soll, angepasst sind. Was einst ein wenig nach Science-Fiction klang, ist heute erfreuliche Realität.

Neben solchen Besonderheiten kommt der 3D Druck auch oft im Bereich der Zahnmedizin zum Einsatz. Im medizinischen Apparatebau wird ebenfalls die 3D Drucktechnik genutzt. Selbst medizinisches Equipment kann mit Hilfe eines 3d Druckers schnell und effektiv hergestellt werden.

Das Träume und Ideen aus der Anfangsphase des 3D Drucks längst Realität sind, bedeutet allerdings nicht zwangsläufig, dass keine neuen Pläne nachwachsen könnten. So sind es heute die sogenannten Bioprints, von denen die Branche und zahlreiche Experten hoffen, dass sie jetzt immer besser in Fahrt kommen. Darüber könnten ganze Organe gedruckt werden. Doch unter Bioprints versteckt man auch Knochen oder Knochenteile sowie Gewebe.

Natürlich müssen die fertigen Drucke auch im Bereich der Medizintechnik eine ganze Menge aushalten können. Drucke, die für ein Unternehmen aus der Medizintechnik gefertigt werden, müssen vom Material her sterilisierbar sein. Darüber hinaus müssen sie biokompatibel sein. Bei unseren Produkten garantieren wir Ihnen natürlich auch die Beständigkeit der fertigen Drucke gegen Chemikalien wie:

- Aceton

- Alkohol

- Medical Materialien

- Biokompatibel

- Metalle wie Edelstahl oder Titan

- Beständigkeit gegenüber Chemikalien wie Aceton, Alkohole, etc.

Geeignete Technologie: Vakuumguss, MJF, SLS, High Resolution, SLM

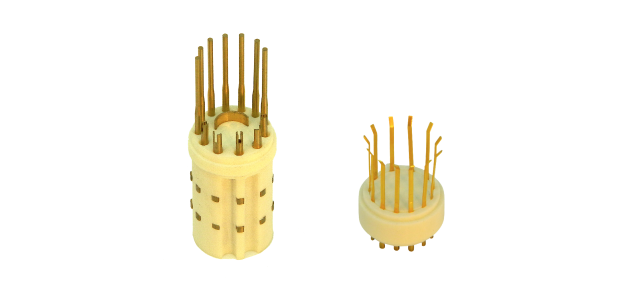

Maschinenbau

Ein weiteres spannendes Betätigungsfeld für unsere 3D Drucker ist der Maschinenbau. Hier kommt die Additive Fertigung vor allen Dingen zum Tragen, wenn es um die Produktion kleinerer Stückzahlen geht.

Wir realisieren dabei gern nach Ihren Vorstellungen kleine und größere Mechanik Bauteile und Dichtungen. Auch Abdeckungen und Verkleidungen in den verschiedensten Größen können wir hier für Sie realisieren. Ihre Vorteile, wenn Sie sich für 3D Druck Produkte aus unserer Herstellung entscheiden, liegen zum Beispiel darin, dass wir hier auf höchste Qualität achten. Abriebfeste Bauteile sind dabei ebenso eine Selbstverständlichkeit wie Werkstücke, die aufgrund eines Faserverstärkter Kunststoffs besonders robust daherkommen. Dabei können wir Ihnen gleichermaßen hochpräzise Kleinstteile im Millimeterbereich oder deutlich größere Druckprodukte anbieten. Selbst komplette Baugruppen liefern wir Ihnen gern vormontiert.

- Abriebfeste Bauteile

- Endlackiert

- Hochpräzise Kleinstteile im Millimeterbereich bis hin zu einer Bauteilgröße bis zu 1.000 x 1.000 x 2.000mm

- Beständigkeit gegenüber Chemikalien wie Aceton, Alkohole, etc.

- Komplette Baugruppen vormontiert geliefert

- Normteile wie Gewindebuchsen oder Lager direkt umgossen/umspritzt

Geeignete Technologie: Vakuumguss, MJF, SLS, SLM, HR

Motorsport

Auf den ersten Blick bringt man Motorsport und 3D Druck nicht unbedingt zusammen. Doch gerade unsere Spezialisierung auf Einzelanfertigungen und Kleinserien ist ein wichtiger Grund dafür, dass wir seit Jahren ein kompetenter Partner verschiedener Abnehmer aus dem Bereich des Motorsports sind.

Einer der größten Erfolge eines unserer Partner im Bereich des Motorsports war die Weltmeisterschaft in der Formel 1 im Jahr 1999. Denn im Weltmeisterauto von Mikka Häkkinen fuhren 3D gedruckte Bauteile aus unseren 3D Druckern mit.

Was sich bis heute nicht geändert hat, ist unsere Begeisterung für Perfektion. Denn genau diese wird für Bauteile in einem so anspruchsvollen Sport wie dem Motorsport benötigt. Hier gilt es maximale Ansprüche an Normen und Performance zu erfüllen und dabei gleichzeitig Perfektion in Sachen Widerstandsoptimierung zu bieten.

- Unsere Produkte für den Motorsportbereich sind hitzebeständig bis 300 Grad Celsius.

- Die besondere Gestaltung der faserverstärkten Materialien verleiht unseren Druckmodellen außergewöhnlich große Stabilität.

- Auch sie erfüllen die Brandschutzbestimmungen gemäß UL94-V0.

- Durch die jahrelange Erfahrung im Motorsport gelingt es unseren Mitarbeitern auch immer wieder, topologieoptimierte Bauteile mit einem möglichst niedrigen Gewicht bei einer Performancesteigerung im Bezug zu vergleichbaren Produkten zu fertigen.

Da hier keine Einschränkungen in der Konstruktion vorliegen, können wir uns zusammen mit Ihnen bei der Entwicklung und Umsetzung neuer Bauteile voll und ganz auf die Steigerung Ihrer Performance konzentrieren. Auch Sie wüssten gern, wie Sie von der jahrelangen Erfahrung und der Expertise unserer Mitarbeiter profitieren können? Wenden Sie sich doch einfach vertrauensvoll an unseren Kundendienst. Dank hoher Flexibilität und sehr kurzer Reaktionszeiten können wir Ihnen sicherlich auch kurzfristig aus der einen oder anderen Patsche helfen.

- Hochtemperaturbeständig bis über 300°C

- Brandschutz gemäq UL94-V0

- REACH/RoHS Konform

- Faserverstärkte Materialien (GFK, CFK)

- Hohe Flexibiliät und kurze Reaktionszeit unserer Kundenbetreuung

- Topologieoptimierte Bauteile; Gewichtsreduzierung bei gleichzeitiger Performancesteigerung

- Keine Einschränkungen in der Konstruktion, das Bedeutet vollen Fokus auf die Performancesteigerung

Luft und Raumfahrt

Sie war eine der ersten Branchen, in der man die Vorteile des 3D Drucks erkannt und schnell und zielgerichtet für sich genutzt hat. Das hat zur Folge, dass Raumfahrtunternehmen seit nunmehr rund 3 Jahrzehnten ihre fertigen Modelle mit Leichtbauteilen aus dem 3D Druck bestücken. Gerade in einem Bereich wie der Luft- und Raumfahrt ist Perfektion absolut unerlässlich.

In kaum einer anderen Branche sind die Materialien einem so enormen Druck und so schwierigen Verhältnissen ausgesetzt. Das bedeutet, dass hier sowohl eine hohe Temperaturbeständigkeit wichtig ist – aber parallel dazu auch ein hohes Maß an Festigkeit und Robustheit. Auch dem Brandschutz muss bei der Entwicklung der Bauteile aus dem 3D Drucker natürlich genügt werden. Den besonderen Anforderungen in Sachen Festigkeit wird durch die Nutzung faserverstärkter Materialien Rechnung getragen.

Albtec hat sich hier in den letzten Jahrzehnten als ein echter Partner in Sachen Entwicklung, Beratung und Produktion für die Branche erwiesen. Gern lassen wir auch Sie einen Anteil an unserer Expertise haben.

- Brandschutz gemäß UL94-V0

- Faserverstärkte Materialien (GFK, CFK)

- Hochtemperaturbeständig bis über 300°C

- Topologieoptimierte Bauteile; Gewichtsreduzierung bei gleichzeitiger Performancesteigerung

Geeignete Technologie: Vakuumguss, MJF SLS

Konstruktionsbüro

Sie sind die Ideenschmieden unserer Zeit – in Konstruktionsbüros werden neue Entwicklungen angestoßen und auf den Weg gebracht. Hier wird an der steten Verbesserung von Maschinen und Geräten gearbeitet. Auch Arbeitsabläufe an sich stehen immer wieder auf dem Prüfstand. Forschung und Entwicklung gehen hier Hand in Hand.

Da ist es nur logisch, dass eine derart zukunftsweisende Branche auch von einer zukunftsweisenden Technologie profitieren kann. Wir helfen Ihnen dabei, Ihren Ideen eine Gestalt zu geben. So können Sie beispielsweise im Rahmen des Rapid Prototyping einen fertig gedruckten und voll funktionsfähigen Prototypen Ihrer Idee in Händen halten. So haben Sie die Möglichkeit, diesen Prototypen erst einmal auf Herz und Niere zu testen und bei Bedarf weitere Modifizierungen vorzunehmen.

Wir bieten Ihnen eine schnelle Bearbeitung Ihres Auftrages und damit verbunden eine sehr zeitnahe Lieferung – was wiederum gerade in der Phase der Entwicklung oder Optimierung eines Geräts durchaus wichtig sein kann. In vielen Fällen liegt unsere Lieferzeit dabei unter 24 Stunden.

- Schnelle und kostengünstige Realisierung von Bauteilen und Baugruppen

- Breite Material- und Technologieauswahl

- 2K-Bauteile

- Lieferzeit innerhalb 24Stunden

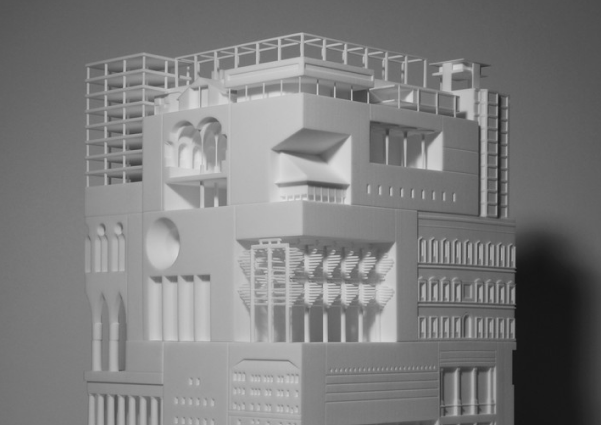

Architekten

Sie sind Architekt und möchten Ihren Kunden die Möglichkeit geben, die Ideen und Projekte, die Ihnen vorschweben, in einem nachvollziehbaren Maßstab zu sehen? Dann ist der 3D Druck die perfekte Lösung für Sie. Immer mehr Architekten setzen auf Modellhäuser und kleines Modellmobiliar. So lässt sich am einfachsten eine konkrete Planung vornehmen.

Die Nutzung des 3D Drucks bringt für einen Architekten eine Menge Vorteile mit sich. Durch die schnelle Umsetzung von Ideen in einen 3D Druck beispielsweise dauert die Planung und Gestaltung eines Gebäudes oft gar nicht mehr so lang. Nutzen auch Sie die Chance auf eine einzigartige Visualisierung Ihrer Entwürfe.

Gern stehen unsere Kollegen vom Kundendienst Ihnen zur Verfügung und beraten Sie bei der Frage, wie Sie den 3D Druck am sinnvollsten für Ihr Unternehmen können.

Messemodelle

Hierbei geht es weniger um eine konkrete Branche – diesen Service können eigentlich alle Branchen gleichermaßen nutzen. Wenn Sie einen Stand auf einer Messe vorbereiten, dann brauchen Sie einerseits Beispiele ihrer Produkte am Stand. Andererseits möchten Sie vielleicht auch einige Produkte direkt am Stand verkaufen und benötigen dafür voll funktionsfähige Produkte.

Von reinen Designteilen für die Vitrine bis hin funktionalen Baugruppen, die eine starke Beanspruchung überstehen müssen, gibt es hier endlose Möglichkeiten. Letztlich fertigen wir die von Ihnen bestellten Teile zur Gänze nach Ihren Vorgaben.

Dabei können Sie beispielsweise von Produkten profitieren, die endlackiert in Farbe und Oberfläche sind. Dabei ist für uns jede Größe realisierbar. Gern erstellen wir Ihnen auch komplette Baugruppen endlackiert und abschließend montiert. Auf Wunsch liefern wir Ihnen die Produkte für Ihren Messestand auch sehr kurzfristig vor einer Messe. Schon nach wenigen Tagen haben Sie die bestellten Modelle vorliegen. Die ansprechende und langlebige Verpackung rundet das Angebot an der Stelle hervorragend ab.

- Endlackiert in Farbe und Oberfläche nach Wahl

- Jede Größe realisierbar

- Komplette Baugruppen endlackiert und montiert

- Auf Wunsch direkt in passender, langlebiger Verpackung

- Kurzfristig auch wenige Tage vor Messebeginn umsetzbar

Büromöbel

Natürlich wird kein kompletter Stuhl im 3D Drucker erstellt. Doch verschiedene Klein- und Einzelteile aus Kunststoff und Metall lassen sich wunderbar im 3D Drucker fertigen. Der große Vorteil dabei: Sie können auch Kleinstbestellungen aufgeben. Dabei bietet jedes Design, das wir Ihnen nach Ihren Vorgaben liefern, ein Höchstmaß an Belastbarkeit.

Auch diese Produkte stellen wir Ihnen endlackiert in Farbe und Oberfläche nach Wahl zur Verfügung.

- Endlackiert in Farbe und Oberfläche nach Wahl

- Design- und einfache Funktionsteile herstellbar

Geeignete Technologie: Vakuumguss, MJF, SLS, HR

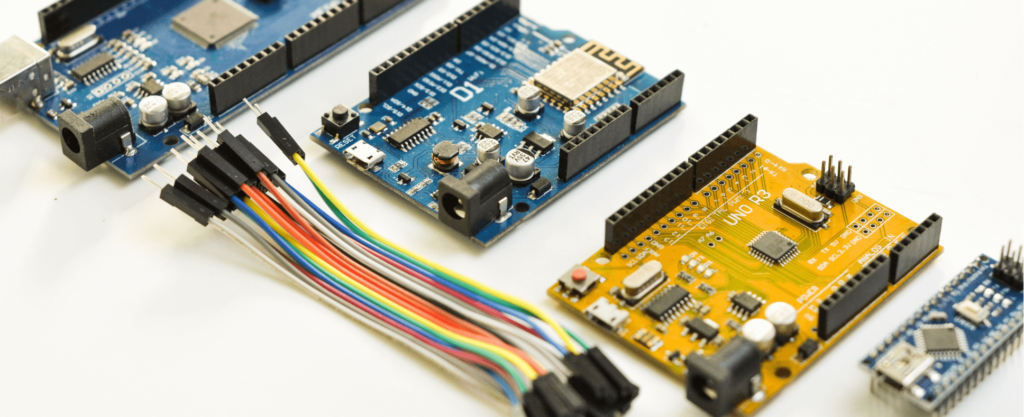

Elektronik & Elektronische Geräte

Viele elektronische Geräte haben ein Kunststoffgehäuse oder kommen mit zahlreichen anderen Kunststoffbestandteilen daher. All diese Bestandteile lassen sich beispielsweise in einem 3D Drucker herstellen. Wenn Sie sich für Produkte aus dem 3D Druck des Hauses Albtec entscheiden, profitieren Sie von einer hohen Durchschlagsfestigkeit.

- Hohe Durchschlagsfestigkeit

- Brandschutzklassifizierung nach UL94-V0

- Hochtemperaturbeständig bis über 300°C

- REACH/RoHS Konform

Geeignete Technologie: Vakuumguss, MJF, HR

Mit dem 3D Druck in vielen Branchen in Richtung Zukunft unterwegs

Es gibt kaum etwas Wichtigeres als Fortschritt in der Wirtschaft und der Industrie gleichermaßen. Entwicklung und Forschung sind die Antriebsfedern unserer Industrie und Wirtschaft. Mit unseren Produkten aus dem 3D Drucker – gefertigt natürlich zu 100 Prozent nach Ihren Vorgaben – unterstützen wir Sie kompetent und nachhaltig bei der Planung und Produktion Ihrer eigenen Modelle.

Sie möchten auch wissen, wie Sie vom 3D Druck in Ihrer Branche profitieren können? Dann sprechen Sie doch einfach unseren Kundendienst an. Gern stehen wir Ihnen zur Seite und helfen Ihnen dabei, auch für Ihr Unternehmen das Optimum aus den Möglichkeiten eines 3D Druckers für Ihre Branche zu ziehen.