3D-Druck – Eine Produktionsart mit Zukunft

Das diese additiven Produktionsarten sehr viel Potenzial für die Zukunft mitbringen, ist inzwischen unbestritten. Nur wie genau diese Zukunft aussieht und wie groß der Anteil sein wird, den der 3D-Druck am klassischen Herstellungsverfahren haben wird, ist nach wie vor fraglich. Bleibt die Frage, was genau 3D-Druck eigentlich ist und warum er für so viele Industrie- und Fertigungszweige sowie für das Gesundheitswesen so interessant sein kann.

Was genau ist eigentlich der 3D-Druck?

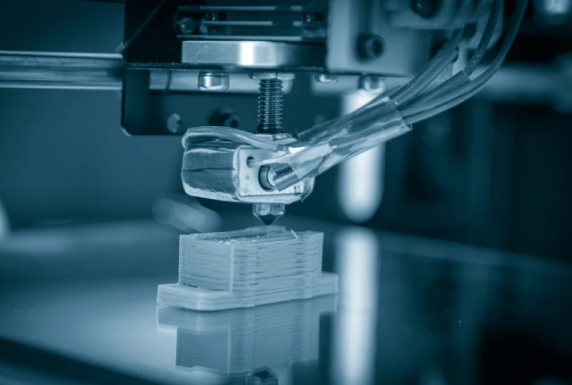

Der Begriff 3D-Druck ist ein Oberbegriff für verschiedene additive Druckverfahren. Als additives Verfahren bezeichnet man ein Produktionsverfahren, bei dem ein Objekt durch Hinzufügen verschiedener Stoffe entsteht. Bei einem 3D-Drucker wird das zu druckende Objekt im Laufe des Druckvorgangs neu gebildet.

Das stellt den größten Unterschied zu klassischen Produktionsvarianten wie der spanenden Bearbeitung dar. Bei diesen Varianten wird das zu fertigende Objekt aus einem bestehenden Materialblock herausgearbeitet. Dabei wird das überschüssige Material im Rahmen der Bearbeitung abgetragen.

Damit ein 3D-Drucker arbeiten kann, ist zuerst die Fertigung eines entsprechenden Computermodells erforderlich. Dieses wird als technische Zeichnung mit einem klassischen CAD-Programm angefertigt. Erst die Kombination aus der technischen Zeichnung mit dem 3D-Drucker kann ein entsprechendes Werkstück gefertigt werden.

Die verschiedenen Verfahren im 3D-Druck im Überblick

Der Begriff 3D-Druck steht als synonym für verschiedene additive Verfahren. Dabei gibt es insbesondere drei verschiedene Varianten:

This is the heading

Das Fertigen eines Objektes durch das Beifügen zähflüssigen Materials

This is the heading

Die Fertigung eines Objektes durch flüssige Photopolymere, die anschließend durch UV-Licht aushärten (Stereolithografie)

This is the heading

Die Fertigung eines Objektes durch das Aufbringen von Materialpulver, das anschließend durch Schmelzprozesse und chemische Reaktionen zu einem Objekt zusammenwächst

Ein kurzer Überblick – die Entwicklung des 3D-Drucks

Das Verfahren der Stereolithografie wurde bereits im Jahr 1984 von Chuck Hill entwickelt. Zum Ende der 80er-Jahre des letzten Jahrhunderts folgte die Entwicklung weiterer additiver Produktionsverfahren. Erst im Jahr 2016 kamen Verfahren auf den Markt, die den 3D-Druck so effektiv und günstig machten, dass eine Fertigung in breiter Masse immer mehr Sinn machte.

Dass der Markt in Sachen 3D-Druck dadurch eine ganz neue Dynamik erhalten hat, ist vielen Unternehmen insbesondere in der Fertigungsindustrie nicht verborgen geblieben. Denn der 3D-Druck hat eine Menge spannender Vorteile für die Produktion der Zukunft im Gepäck. Je nach weiterer Entwicklung der Drucker in diesem Bereich kann das auch weitreichende Folgen für verschiedene andere Industriezweige mit sich bringen.

So läuft die Produktion mit einem 3D-Drucker

Die Produktion mit einem 3D-Drucker erfolgt im Rahmen eines vierstufigen Produktionsprozesses. Dieser sieht folgendermaßen aus:

Erstellung eine 3D-Modells

Die Vorbereitung vor dem Druck

Der Druck selbst

Nachbearbeitung des Druckobjektes

Die Vorbereitung vor dem Druck

Zwei weitere Arbeitsschritte sind notwendig, ehe der Druck starten kann. Diese sind im Bereich der Vorbereitung zusammengefasst.

Als erstes müssen Sie das 3D-Modell reparieren. Das bedeutet, dass Sie Ihr Modell mit einer entsprechenden Software auf Fehler untersuchen und diese beseitigen müssen. Das können Sie inzwischen mit verschiedenen Softwarelösungen selbst erledigen. Alternativ gibt es Experten, die 3D-Modelle entsprechend kontrollieren und Fehler beheben

Im nächsten Schritt erfolgt die unmittelbare Vorbereitung des Modells selbst. Dieser Arbeitsschritt wird als “Slicen” bezeichnet. Dabei wird das Modell für den Druck in verschiedene Schichten zerlegt. Diese Schichten legen den anschließenden Fertigungsprozess im 3D-Druck fest. Wenn Sie selbst den Druck erledigen, müssen Sie auch das Slicen selbst erledigen. Die dafür notwendige Software ist in der Regel in Ihrem 3D-Drucker enthalten.

Wenn Sie ein Unternehmen mit dem Druck Ihrer Objekte beauftragen, erfolgt das Slicen bei der druckenden Stelle.

Der Druck selbst

Wie schnell der Druck selbst vonstattengeht, ist abhängig vom Druckverfahren. Je nach angewandten Verfahren dauert der Druck zwischen mehreren Stunden und einigen wenigen Tagen. Manche schnelleren Verfahren schaffen heute bereits mehrere cm in der Stunde – andere bringen einen Fortschritt von wenigen mm in der Stunde.

Nachbearbeitung des Druckobjektes

Das ein Objekt aus dem 3D-Drucker entnommen und sofort verwendet werden kann, kommt so gut wie nie vor. Tatsächlich bedarf es nach dem eigentlichen Druck noch einiger Nachbearbeitung. Wie genau diese Nachbearbeitung aussehen muss, ist vor allem von der Art der Fertigung im Rahmen des 3D-Drucks abhängig.

Die notwendigen Arbeiten können sich dabei vom einfachen Nachpolieren bis zur Nachbearbeitung im Rahmen eines zerspanenden Prozesses erstrecken.

Vorteile eines 3D-Druckers

Die Fertigung von Objekten im 3D-Drucker bringt eine Menge Vorteile mit sich. Da wäre beispielsweise der Umstand, dass der Materialverlust im Rahmen der Fertigung mit einem 3D-Drucker sehr gering ist. Denn während beim zerspanenden Verfahren ein Materialblock vorhanden ist, von dem eine Menge abgetragen werden muss, wird das Objekt im 3D-Druck quasi aus dem Nichts schichtweise aufgebaut.

Dadurch ist der Materialverlust hier minimal. Nicht verwendete Materialien können für den nächsten Druck genutzt werden. Allein im Rahmen der Nachbearbeitung kann es zu einem gewissen Materialverlust kommen. Wenn beispielsweise Stützkonstruktionen nach dem Druck entfernt oder die Oberflächen eines Objektes abgeschliffen werden müssen, fällt hier ein minimaler Materialverlust an.

Ein weiterer wichtiger Punkt ist die Komplexität der Objekte, die hier gefertigt werden können. So kann im 3D-Druck ein Objekt mit Hohlräumen, Leitungsschächten und komplexen geometrischen Linienführungen gefertigt werden. Im klassischen spanenden Herstellungsverfahren wären dafür mehrere Fertigungsschritte mit der Herstellung unterschiedlicher Objekte notwendig. Diese müssten im nächsten Schritt teils aufwendig zusammengefügt werden. Das wiederum macht das fertige Objekt anfälliger für Fehler und Schäden.

Unter dem Strich lässt sich also sagen, dass die Fertigung im 3D-Druck im direkten Vergleich zum spanenden Verfahren ökologisch nachhaltiger und deutlich kosteneffizienter daherkommt.

Auf einen Blick zusammengefasst sehen die Vorteile dabei folgendermaßen aus:

Die Herstellung von Bauteilen ist kosten- und zeiteffizient

Auch komplexe und filigrane Geometrien lassen sich ohne zusätzlichen Aufwand fertigen

Gleiches trifft auf innen liegende Strukturen zu

Der Materialverbrauch und insbesondere der Materialverlust sind hier sehr niedrig

Die Herstellung erfolgt zur Gänze werkzeuglos

Änderungswünsche können schnell und unproblematisch eingearbeitet werden

Durch den Druck von Prototypen lassen sich die Forschung und Entwicklung deutlich vorantreiben

Die Produktion erfolgt vollautomatisch

Welche Materialien können für den 3D-Druck verwendet werden?

Dank der verschiedenen Verfahren im 3D-Druck, können hier auch die unterschiedlichsten Materialien Verwendung finden. Vom Schokoladendruck über Kunststoffe bis hin zu Keramik- oder Metall-Objekten können hier eine Vielzahl von Materialien verwendet werden.

Anwendungsbereiche für die 3D-Druck Verfahren

Die additiven Fertigungsverfahren finden heute in immer mehr Branchen Anwendung. Das geht quer durch sämtliche Gewerke und Bereiche. Von der Bildung und Forschung über die Raumfahrtindustrie bis hin zur Werkzeugfertigung. Hier einige Beispiele aus der täglichen Praxis.

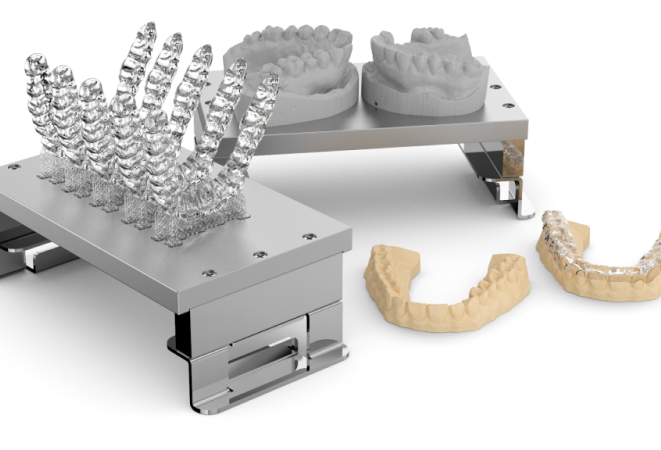

Medizin

Im Bereich der Medizin kann man durch den 3D-Druck mit Fug und Recht von einer Revolutionierung sprechen. Denn durch die additiven Fertigungsprozesse ist es heute möglich, medizinisch notwendige Objekte patientenspezifisch hergestellt werden. Zu nennen wären da beispielsweise:

- Dentalbrücken

- Hörgeräte

- Implantate

- Prothesen

Besonders spannend ist hier die scheinbar bereits in greifbarer Nähe liegende Möglichkeit, ganze Organe in einem 3D-Drucker herzustellen und so Menschen, die lange auf ein transplantationsfähiges Organ warten müssen, das Leben zu retten.

Wissenschaft und Forschung

In der Wissenschaft und Forschung ermöglicht der 3D-Drucker es Forschern und Ingenieuren Dingen, die bisher nur theoretisch diskutiert werden konnten, echte Konturen zu geben. So können beispielsweise Modelle von Tieren, die längst ausgestorben sind, gefertigt werden. Gleiches gilt für konkrete Modelle von historischen Städten oder Regionen.

Im Bereich der Forschung lassen sich durch den 3D-Druck manche Theorien und Ansätze schnell verifizieren oder eben verwerfen.

Bildung

Auch im Bildungsbereich ist hier eine ganze Menge möglich. Da wäre beispielsweise die Fertigung von Anschauungsobjekten für Auszubildende und Schüler.

Automobilbau sowie Luft- und Raumfahrt

Gerade diese drei Bereiche profitieren besonders von den Vorteilen des 3D-Drucks. Denn in kaum einem anderen Bereich werden so klar und spezifisch geformte und durchgeplante Objekte mit einer so hohen Belastbarkeit benötigt wie hier. Vor allem die Vielfalt an Materialien, die für den 3D-Druck zum Einsatz kommen können, machen diese Fertigungsmethode für die drei genannten Branchen so interessant.

Industrie und Bau

Tatsächlich ist das der Bereich, in dem diese Fertigungsvariante am häufigsten zum Einsatz kommt. Ob große Bauteile oder wichtige Werkzeuge für den Bau – im 3D-Druck lässt sich eigentlich alles herstellen, was in der Industrie und auf dem Bau benötigt wird. Das Ganze mit sehr geringem Materialverlust und zu überschaubaren Kosten.

Kunst

Die Bildung neuer Kunstgegenstände ist ebenso möglich wie die originalgetreue Fertigung von Duplikaten oder der Nachbau nicht mehr vollständiger oder komplett zerstörter Kunstwerke.

Mode und Schmuck

Ob Schmuck oder Modebestandteile wie Gürtelschnallen – dank additiver Fertigung lassen sich auch sollte Dinge schnell und recht unkompliziert herstellen.

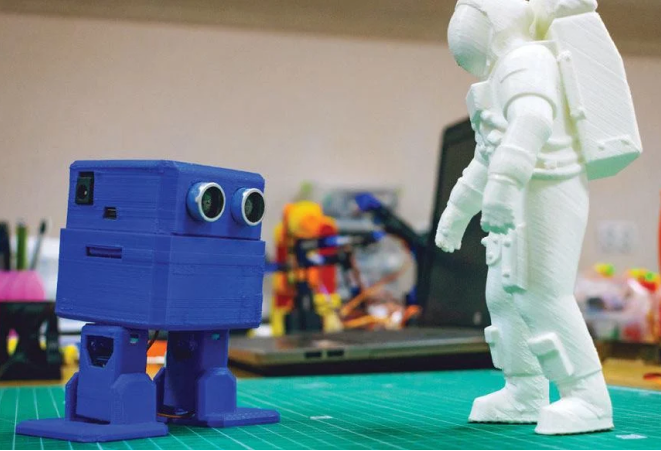

Hobby

Ein klassisches Beispiel aus dem Hobbybereich sind Modellbauteile, die schnell und effizient im 3D-Drucker hergestellt werden können.

Zukunftsaussichten des 3D-Drucks

Die Möglichkeiten im Bereich des 3D-Drucks sind riesig. Von der möglichen Aussicht, dass nahezu sämtliche Fertigung irgendwann einmal auf diesem Weg erfolgen wird bis zum stark selektiven Einsatz in den oben genannten Branchen ist hierbei alles möglich. Die Frage dabei wird sein, wie sich der 3D-Druck in den nächsten Jahren weiterentwickelt und wie stark die Preisspirale für viele herkömmliche Fertigungsprozesse in Zukunft noch ansteigt.

Das der 3D-Druck eine gute Alternative für viele andere Fertigungsmethoden ist, ist schon lange kein Geheimnis mehr. Nicht unterschätzen sollte man in Zukunft auch die Chance, die Vorteile einer stark dezentralisierten Produktion zu nutzen. Wenn jedes Unternehmen seine eigenen 3D-Drucker verwenden kann, um alle notwendigen Teile termingetreu selbst herzustellen, spart dies nicht nur eine Menge Geld. Das Verkehrsaufkommen in Sachen Lkws auf den Straßen würde drastisch zurückgehen, was wiederum in Sachen Umweltschutz und Erreichen der Klimaziele ein wichtiger Baustein sein könnte.

Außerdem reduziert sich die Abhängigkeit von Lieferketten. Wie unzuverlässig diese sein können, mussten viele Unternehmen in den letzten Jahren um Rahmen der Corona-Pandemie oder des Krieges zwischen Russland und der Ukraine feststellen.