Multi Jet Fusion

How Multi Jet Fusion works

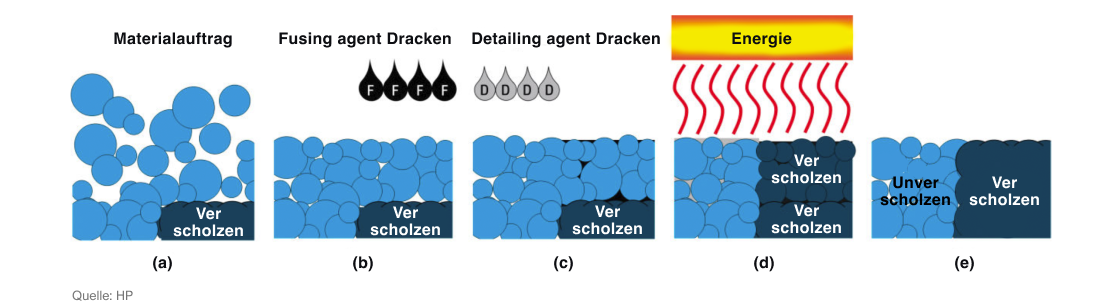

Similar to SLS, the starting material for MJF is an extremely fine powder. An 80 µm thick layer of powder is applied to the build platform using a roller. The print head then moves over the platform and prints the contours of the components onto the powder using a black heat-attracting liquid, the so-called fusing agent.

At the same time, the entire powder bed is heated evenly by heat lamps. A higher temperature is now created where the fusing agent was applied and the powder melts exactly there. In contrast to SLS, no laser is used to scan and fuse the contour; instead, the entire platform is heated and only the contour processed by the fusing agent is fused.

In order to create sharp edges and fine details, the so-called detailing agent is applied around the areas with the fusing agent. This liquid is heat-repellent and ensures clear separations and prevents unwanted fusing of the nearby powder. The two agents are applied by spraying on millions of micro-droplets, a highly precise process that ensures maximum detail. Once the layer of powder has been applied and fused in places using the two agents, the first layer is ready. This process only takes about 10 seconds and is repeated thousands of times until the complete print job is finished.

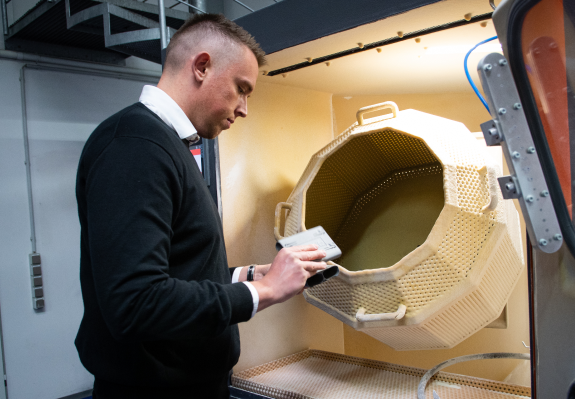

As with SLS, the build chamber has to cool down for a few hours after printing the components, but the printing and cooling times are significantly shorter in Multi Jet Fusion. The components are then separated from the loose powder and processed further. The loose powder is fed back into the process and mixed with fresh material. By mixing only 20% fresh and 80% used powder, we work in a way that conserves resources and is extremely cost-effective. The standard material in Multi Jet Fusion is polyamide 12.

The advantages of Multi Jet Fusion

Thanks to its special mode of operation, Multi Jet Fusion has a number of advantages over other additive and conventional manufacturing processes, such as milling or injection molding.

- Thanks to the layered construction method in MJF, the user has virtually no limits when designing components. There is no need to worry about bevels or undercuts, as these no longer play a role in the MJF process. Multi Jet Fusion also has a number of other advantages.

- No tools or molds are required for the manufacturing process. The production of the tools takes several weeks and is very cost-intensive. This investment ties up your capital and weakens your cash flow. Especially in prototyping and for the production of small batches, tool-free production saves a lot of time and money.

- The freedom of design in Mutli Jet Fusion means that functional integration is possible. This means that functional components such as snap-in hooks, air channels for vacuum grippers or hinges can be integrated directly into the component during the assembly process. This saves assembly steps and therefore time, money and potential sources of error.

- “Just-in-Time” and ‘Just in Sequence’. Two important concepts that are easy to implement in the MJF. Production runs entirely according to demand and prevents large stocks that tie up capital.

- Geometry adjustments are no problem in the MJF. Thanks to the short product cycles, subsequent changes to components are no longer an exception. The next components can be manufactured according to the latest data status at the same time as the CAD model is changed. And as large stock levels have been avoided, there are no more old components in stock.

- The short production times significantly reduce the time-to-market, as each part can be printed and then tested in parallel with the component development. What used to be a months-long process is now implemented in just a few days.

MJF vs SLS

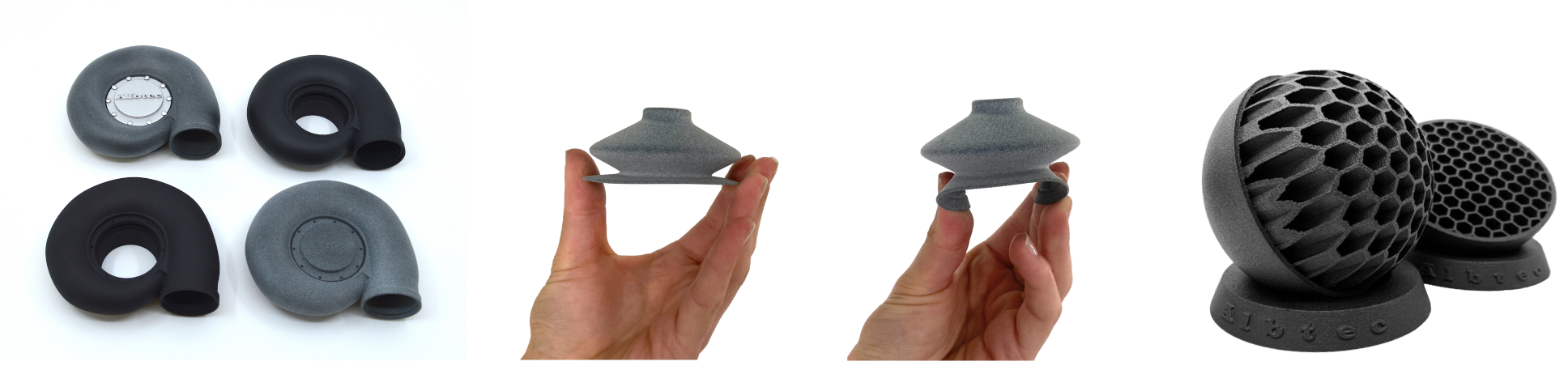

Multi Jet Fusion and Selective Laser Sintering are very similar in many respects, but there are significant differences that need to be considered. By using the black fusing agent, gray components are obtained instead of white components as in SLS. The use of particularly fine powder (grain size of 64µm) and the extremely thin layers of only 80µm in Multi Jet Fusion leads to components with smooth surfaces and significantly finer pores than in SLS. Further significant differences between the two processes are described below.

Material density:

In Multi Jet Fusion, the powder is completely melted, giving the components a density that is up to 10% higher. In SLS, as the name suggests, the components are merely sintered. In the sintering process, the powder is heated to just below the melting point and the powder particles do not fully bond together.

Isotropy:

Isotropy means that a component has the same strength in all three dimensions. Due to the complete melting in the MJF, these components are considered isotropic. In SLS, as in most other 3D printing technologies, the problem is that the joint is not as stable in the Z direction.

Speed:

Thanks to the extremely high speed of the MJF, thousands of components can be printed overnight. With subsequent cooling and reworking, this results in a throughput time of up to 2 days for a complete assembly space. In selective laser sintering, the printing process takes significantly longer, as the thin laser naturally takes longer than full-surface heating in the MJF.

Accuracy and resolution:

Multi Jet Fusion technology offers a layer thickness of 80 µm and a resolution of 1,200 dpi. Laser sintering does not achieve this high resolution despite the precise laser.

Waterproof:

Multi Jet Fusion components are waterproof without further post-treatment, whereas SLS components are not.

Application of Multi Jet Fusion

In addition to fast production in rapid prototyping within a few days, the Multi Jet Fusion is primarily used in additive manufacturing. This means that it is primarily used to produce series components in quantities of up to 10,000 units. In this area, the tool costs still account for a very large proportion of the costs in injection molding. Production in MJF eliminates these high investment costs and series components are produced within a few days.

This is particularly profitable for companies that only produce small quantities of their products. Corporations also use the MJF to produce pre-series. The MJF is a cross-industry technology that is used not only in the automotive industry and medical technology, but also in aerospace and mechanical engineering. The advantages of Multi Jet Fusion are particularly decisive in the medical sector when it comes to prosthetics and implants.

Materials

The Multi Jet Fusion mainly processes polyamides and elastomers. We offer you a wide range of materials to achieve the right properties for every application.

PA 12

PA 11

PA 12 GF

PP

TPU

Postprocessing in MJF

Unprocessed MJF components have a grey color and are comparatively smooth. However, the surface can be smoothed even further. The color can also be changed afterwards.

Varnishing

MJF components are easy to paint in the color of your choice.

Surface finish

We can finish the surfaces mechanically by grinding and polishing to your specifications.

Vapour smoothing

A brief treatment in a chemical steam bath smoothes the surface and closes the pores. The result is a smooth surface like injection molding.

Coloring

The components are dyed in a dye bath. After the dyeing process, the components have a deep black color.

Shot peening

In order to smooth the surface of the components and close the pores, there is the option of compaction blasting. This involves blasting the component with plastic beads.

Trowalizing

In this process, incredibly smooth surfaces can be achieved and the components can even be polished.