Polyjet

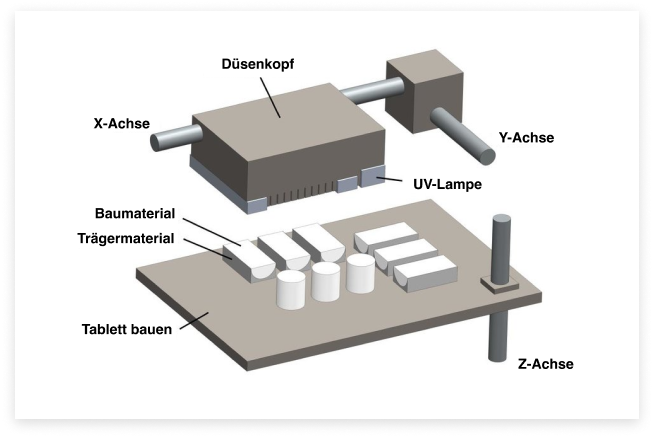

Funktionsweise Polyjet

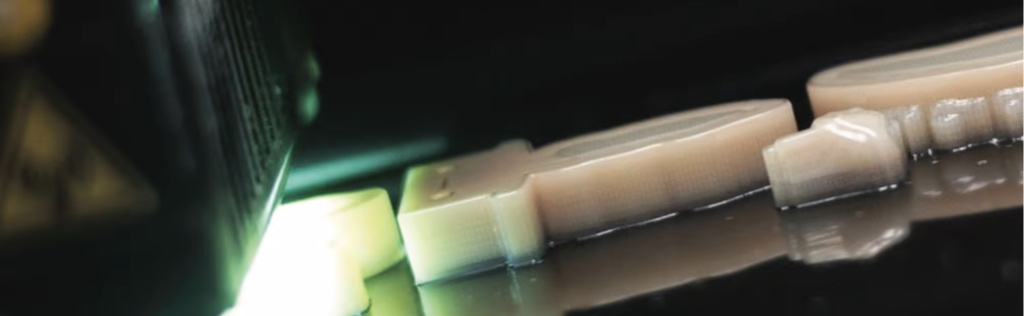

Die patentierte Technologie ist einzigartig auf dem Markt der 3D-Drucker. Als Ausgangsmaterial dienen hier flüssige photoreaktive Kunststoffe. Der Druckkopf fährt Schicht für Schicht über die Bauplattform und über unzählige kleine Düsen werden die Materialien auf die Plattform gesprüht und direkt mit UV-Licht ausgehärtet. Durch verschiedene Düsen können unterschiedliche Materialien zeitgleich gedruckt werden.

Polyjet 3D-Druckverfahren

Vorteile des Selektiven Lasersintern

Durch die spezielle Funktionsweise, weist das Selektive Lasersintern eine Vielzahl an Vorteilen gegenüber den anderen additiven und den konventionellen Fertigungsverfahren, wie zum Beispiel Fräsen oder der Spritzguss, auf. Durch die Schichtbauweise im SLS hat man als Anwender quasi keine Grenzen im Design der Bauteile. Weder über Formschrägen noch über Hinterschnitte muss man sich Gedanken machen, da das alles im SLS-Prozess keine Rolle mehr spielt. Das Selektive Lasersintern kann noch mit einigen weiteren Vorteilen glänzen.

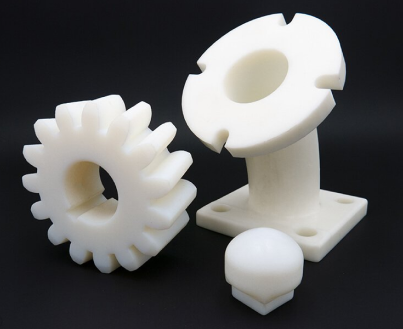

Hoher Detailgrad

Hohe Maßgenauigkeit

Glatte Oberflächen

Über 500.000 Farben

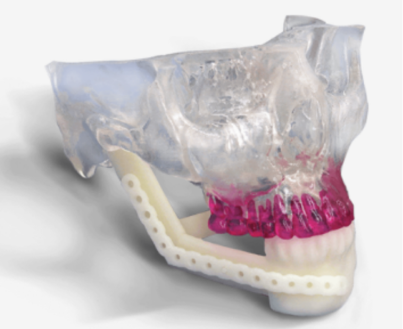

Mehrkomponenten Druck

Materialien

Vero-Materialien

Tango-Materialien

Agilus

Digital-Materialien

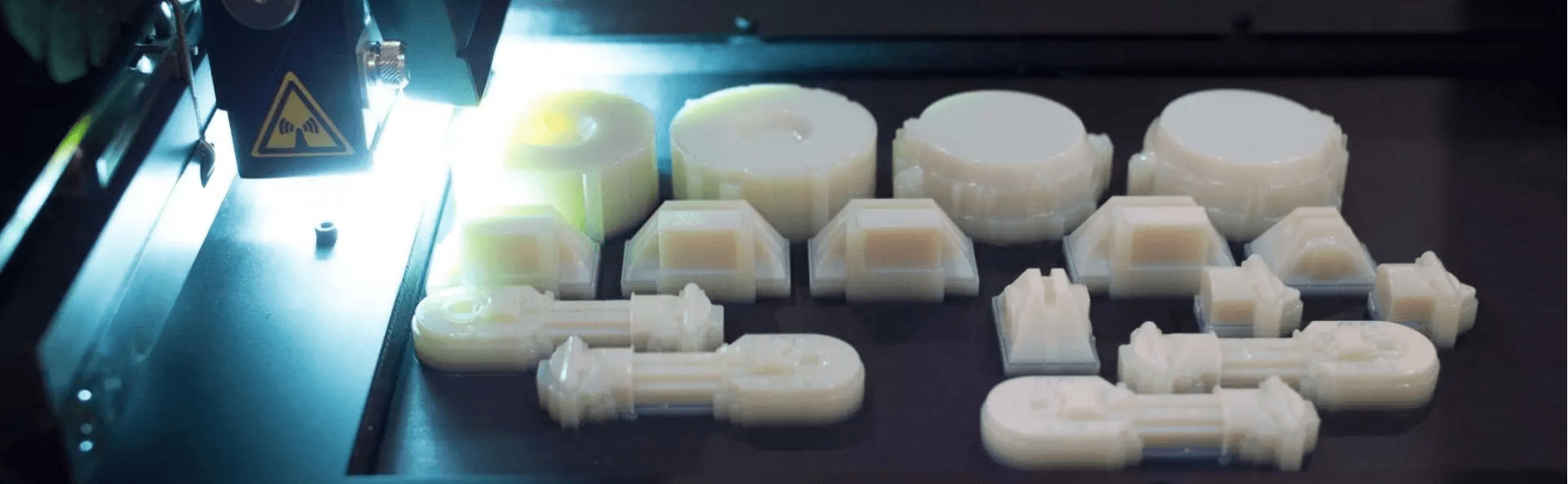

Nachbearbeitung in Polyjet

- Lackieren

- Polieren